Usable for the special sterilization tasks in laboratories. Microprocessor-controlled fully automatic program sequence.

General characteristics for all Systec V-Series model ranges:

- Sterilization temperature up to 140°C, Steam pressure up to 4 bar

- Novel automatic door closure with safety-lock system, lip-gasket out of silicone and opening at the push of a button

- Thermal door lock, controlled by pressure and medium temperature according to Pressure Vessel Regulations

- Pressure vessel made out of high quality pharmaceutical grade Titanium-stabilized stainless steel 1.4571 (V4A, AISI 316 Ti), electro polished, resistant against chemicals, easy to clean

- Housing and basic frame construction out of corrosion resistant stainless steel

- All sterilization programs with pre-selectable sterilization parameters and automatic program sequence

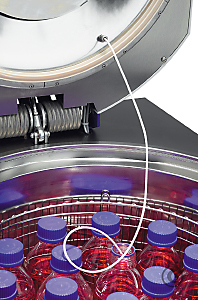

- Flexible PT-100 temperature sensor for reference vessel

- Medium temperature-controlled sterilization time

- Electronic pressure sensor for pressure and temperature control

- Common collector connection for all outlets

- Emptying valve

- Base plate for vessels, baskets etc.

- Validation port

- Prepared for subsequent printer installation

- Thermal insulation out of Hanno-Tect, no risk of particle dissociation

- Safety pressure release valve

- Safety cut off at low water level

- Safety cut off at excess temperature

Special accessories like baskets and inserts, lifting devices, and wheels available on request.

for all laboratory applications with even sophisticated sterilization tasks according newest state-of-the art. With all possibilities of additional options for process optimization to achieve validatable sterilization processes.

Special characteristics for model range Systec VX

- Fully-automatic autoclaves with microprocessor control and 12 programs and 2 test programs:

1-3 Solids

4-5 Waste 2Destruction bags"

6 Liquid waste with controlled steam exhaust for cooling

7 Liquid waste with self-cooling

8-10 Liquid Media with controlled steam exhaust for cooling

11 Liquid media with self-cooling

12 Cleaning

13 Vacuum test*

14 Bowie Dick test program*

15-25 Individually programmable

- From the sterilization chamber separated steam generator integrated into the housing (no heating elements and no water-swamp in the sterilization chamber)

- Additional PT-100 temperature sensor for control of temperature in the condense exhaust

- Steam exhaust condensation, water cooled, thermostatic controlled

- "Autofill" - Automatic de-mineralized water feed for steam generation

- Special program for waste destruction with pulsating heat-up period for improved ventilation of waste bags

- Start by clock / timer for programmed start time

- RS 232 and RS 485 interface for external data transfer (network compatible)

- Internal memory for backup of up to 500 sterilization cycles

- Prepared for subsequent rapid cooling installation

- Prepared for subsequent installation of vacuum system

- Prepared for subsequent drying installation

Optional available:

- Rapid cooling

- Pre- and Post-vacuum

- Air exhaust filtration

- Drying (Superdry)*

- Extension of temperature and pressure to 150°C / 5 bar**

- Documentation devices (Printer / PC-Software)

- Integrated SD-card-reader including SD-card for backup of up to 10.000 sterilization cycles

- More options and special programs on request

(* only in combination with optional vacuum system)

(** only for autoclave range Systec VX-65 up to Systec VX-150)

for elementary laboratory applications and liquid sterilization. With limited availability of additional options for process optimization.

Special characteristics for model range Systec VE

- Fully-automatic autoclaves with microprocessor control and 12 programs:

1-3 Solids

4-5 Waste "Destruction bags"

6 Liquid waste with controlled steam exhaust for cooling

7 Liquid waste with self-cooling

8-10 Liquid media with controlled steam exhaust for cooling

11 Liquid media with self-cooling

12 Cleaning

- Steam generation through heating elements inside the chamber (no separated steam generator)

- Steam exhaust condensation, water cooled, thermostatic controlled

- "Autofill" - Automatic de-mineralized water feed for steam generation

- Special program for waste destruction with pulsating heat-up period for improved ventilation of waste bags

- Start by clock / timer for programmed start time

- RS 232 and RS 485 interface for external data transfer (network compatible)

- Prepared for subsequent rapid cooling installation

Optional available:

- Rapid cooling

- Air exhaust filtration

- Extension of temperature and pressure to 150°C / 5 bar*

- Documentation devices (Printer / PC-Software)

- Internal memory for backup of up to 500 sterilization cycles

- Integrated SD-card-reader including SD-card for backup of up to 10.000 sterilization cycles

- More options on request

(* only for autoclave range Systec VE-65 up to Systec VE-150)

for basic applications without possibilities for process optimization.

Special characteristics for model range Systec VB

- Fully-automatic autoclaves with microprocessor control and 3 programs, with limited application potential:

1 Solids

2 Waste "Destruction bags"

3 Liquids with controlled steam exhaust for cooling

- Steam generation through heating elements inside the chamber (no separated steam generator)

- Special program for waste destruction with pulsating heat-up period for improved ventilation of waste bags

Optional available:

- Printer for documentation

Power supply for Systec VX/VE/VB-40 and -55, 220-240V, single-phase 50/60 Hz, 16A

Power supply for Systec VX/VE/VB-65 up to -150, 380-400V, 50/60 Hz, three-phase plus neutral, 16A

Modification to other voltage and single-phase operation available on request

Prices for options and accessories available on request