- Clearly structured operator panel

- 4-digit LED display

- Indication of setpoint and actual values

- Optionally, temperature control via Pt100

- Programmable fluid temperature in Pt100 mode

- Programmable maximum heater plate temperature

- Programmable safety temperature

- PID control for temperature and motor speed

- Self-optimizing control algorithms for high temperature stability

- Soft start of stirrer motor

- Adjustable switch-off function (timer)

- Auto-switchoff in case of Pt100 failure

- Overtemperature protection

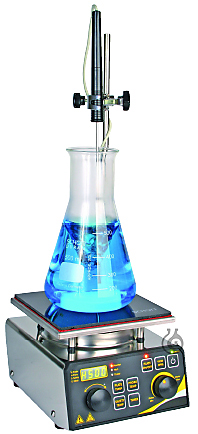

The new, heatable magnetic stirrers of series M21-23 directly indicate the set temperature for heater plate and temperature sensor on the operator panel of the unit. Setpoint temperatures and safety temperatures, as well as the programmable timer for switch-on and -off are easily set via a hand wheel. All parameters can be read from the four-digit LED display. Monitoring of the set motor speed is possible as well.

These powerful magnetic stirrers are equipped with a soft-start function for motor start and stop, and fuzzy logic of fluid and heater plate temperature for fast heating and stabl temperatures.

The acid-resistant stainless steel housing and the stainless steel "collar" between heater plate and enclosure cover prevent fluids and spray from penetrating into the device. All models are available with RS485 interface for simple and quick read-out and entering of all relevant data. Optionally, an RS485 on RS232 adapter is available.

Technical data: |

Voltage: | 110/230 Volt; 50/60 Hz (type label at rear of unit) |

Display: | 4-digit 7-segment LED display |

Motor speed: | - Shaded pole motor, 25 Watt

- 60 - 1,600 min-1

- Microprocessor-controlled soft start of stirrer motor

|

Temperature control: | Microprocessor-controlled (PID control) - heater plate temperature settable in 1° increments up to 350°C/380°C/500°C (M21, M22, M23)

- programmable sample temperature (Pt100)

- programmable heater plate temperature

- programmable safety temperature

|

Safety system: | Recognizes the following events and protects the unit: - breakdown, failure of heater plate (heater plate temperature exceeds max. heater plate temperature)

- breakdown, failure of temperature sensor (broken temperature sensor)

- failure of heater output stage (TRIAC)

- extreme increase or decrease of temperature (temperature sensor falling out of the glass, or glass break)

- Fluid recognition (Out of liquid function)

|

Switching-off delay (timer) | Programmable switching-off delay of the unit

min. switch-off time: 1 minute

max. switch-off time: 999 minutes |

Temperature sensors: | Heater plate: thermocouple

External: platinum temperature sensor (Pt100) |

Setting accuracy heater plate: | 1°C / 1 K (1°F in Fahrenheit mode) |

Setting accuracy Pt100 sensor: | 0 - 100°C: 0.2°C / 0.2K

>100°C: 1°C / 1K

(1°F in Fahrenheit mode) |

Setting accuracy speed: | 10 min-1 |

Control stability at Pt100 mode: | ±0.3°C

(2L H2O with 60°C setpoint temperature, ambient temp.: 23°C. Control deviation at 60 min. test duration.) |

Temperature range of medium: | max. 250°C |

Recommended stirrer bar: | Length: 55 mm (30 - 70 mm)

Diameter: 10 mm (5 - 12 mm) |

Ambient temperature: | 5 - 40°C |

Moisture: | 80% relative humidity |

Class of protection acc. to DIN 40050: | IP32 |

Dimensions: | 210 × 145 × 110 mm |

Weight: | 2.3 kg |