|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chemic ALS - Via S.Francesco d'Assisi, 200 - 70018 Rutigliano (BA) - Italy - tel. (+39)080.476.10.66 - fax (+39)080.476.11.26 - info@labcatalogo.it - www.labcatalogo.it | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Main -> Stirring, shaking systems -> Stirrers -> Stirrers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Overhead Stirrers, Heidolph | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mechanical stirrers RZR series

Technicality Properties

Technicality Data

RZR 2020

RZR 2021

RZR 2041

Electronic stirrers RZR series General Properties

RZR 2051 control

RZR 2052 control

RZR 2102 control

RZR 2102 control Z

Accessories

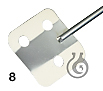

Blade and half-moon impeller

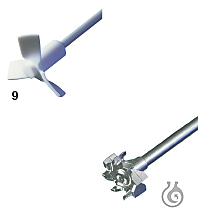

Propeller-type impeller

Radial flow impeller

Anchor-type impeller

Stirring system inoJET® Worldwide the only impeller capable of completely mixing larger quantities of high-viscosity liquids and gels. Principle of Functionality: The worldwide patented inoJET® Mixing System is the result of the so-called cone-principle. Turbulent flows are created at the taper end by acceleration, displacement and retardation. These flows advance throught the stirred medium and result in the new dynamic mixing motion. Your Advantage:

POM = Polyoxymethylene Package RZR 2020

Package RZR 2052

|        |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||