Plasma surface system

The Femto plasma system was mainly developed for the production of small series, laboratory applications and for research and development purposes.

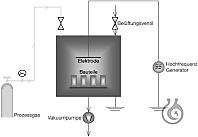

Plasma technology:

The specimen are first placed on product carriers and then placed in the plasma chamber. After evacuating the chamber, a process gas (e.g. oxygen) is supplied. By means of additionally supplying energy, plasma (ionized gas) is generated. The surface of the specimen is cleaned, activated and - for longer process times - also etched through chemical reactions. The vacuum pump continuously pumps out the process gas. The process can be controlled. Different process gases can be used for a variety of new applications.

Application examples:

- Creation of highly pure surfaces

- Photoresist incineration

- Asbestos analysis

- Hydrophilic, hydrophobic

- Adhesive pre-treatment of metals, plastics, elastomers and ceramics

- Pre-treatment prior to printing, lacquering bonding, adhering...

- Reduction of oxidized surfaces

- Solder pre-treatment

- Sterilisation

- Etching and texturing of surfaces

- Electron microscopy

- TEM-sample holder (REM)